We are Manufacturer, Supplier, Exporter and Dealer of Ceramic Lined Components, Ceramic Lined Products, Ceramic Lined Bends, Ceramic Lined Pipes etc. Our setup is situated in Pune, Maharashtra, India.

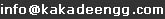

Ceramics is produced from high purity fine grain aluminum oxide. The necessary forming of shapes is done in its green or pre sintered phase. The products are then sintered in a klein at extremely high temperature.

| Ceramic Lined Bend | Ceramic Lined Components |

|

|

| Ceramic Lined Products | Ceramic Lined Pipes |

|

|

| Ceramic Lined Bends |

|

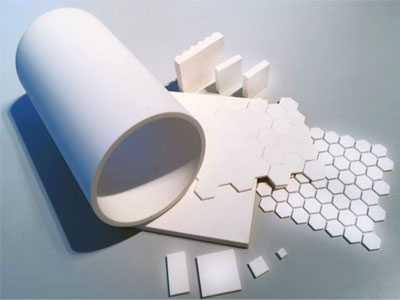

Improve Engineering manufactures a wide range of high alumina ceramic liners such as tiles, special shapes and pipe sections which have high alumina content and wear protection properties. These liners are bonded on to steel surfaces and are extremely effective for prevention of wear and tear due to high particle velocity, impingement, abrasion and impact. They are extensively used for lining of equipment prone to severe wear in core sector industries such as cement, steel, power.

Improve Engineering manufactures ceramic tiles in the form of weldable and pastable tiles as well as pipe sections of various diameters for installation at site and more specifically for lining of fabricated pipes, bends and fittings for pneumatic conveying applications specially for conveying of pulverised coal in thermal power plants .

Alumina powder after ball milling and spray drying are pressed and sintered at high temperature. This sintered product consists of dense alumina with hardness of approximately 9 Mohs and can withstand temperature up to 10000C.

- Ceramic Lined Bends are used for conveying material with high velocity.

- Ceramic lining are used for short radius Bend applications.

- Tile thicknesses range from 6 mm to 50 mm.

- Tube (cylinders) sizes range from 40 to 150 mm ID.

- Tiles – Plain / Tapered, Pastable / Weldeable, Pressed/Cast.

- Alumina content

- Density

- Compressive strength

- Flexural strength

- Hardness on mohs scale

- Water absorption

- Coefficient of thermal expansion

- Abrasion test loss

- Jet erosion test

- Maximum Temperature

Ceramic Tiles

- Min 85%

- 3.3-3.7 gm\cc

- Min 4500 kg\sq cm

- Min 2200 kg\sq cm

- 9 mohs

- Nil

- <8.1x10-6

- 0.1 gms.

- 12 min as per BS 1902

- 1000 deg C